The policy of structural management (including the heavy maintenance) adopted by GEFYRA SA is such as to maintain the Bridge status to the best possible level ensuring a high level of safety for the Users during its whole service life (120 years according to the design). Therefore, the high value of Bridge asset is maintained over the years.

The Contractor with the contribution of the Designers, specialized Suppliers and Consultants has issued a specific Inspection & Maintenance Manual (IMM), approved by the Independent Engineer (Maunsell). This Manual contains the main results of a structural risk assessment performed to identify the major risks and set the management plan during the Bridge service life. Detailed inspection specifications with regards to the level and a schedule are also provided. The Manual along with the As-Built drawings and other Quality documents are valuable tools at the disposal of the Structural Maintenance Department of GEFYRA S.A.

Structural Risk assessment

The structural risk assessment concluded that except the normal ageing and deterioration due to operational loads, which have to be accounted for, particular attention shall be paid to the effect of the adverse environment including the exceptional loads in case of special events such as strong earthquakes, high winds, ship collision etc.

It has to be pointed out that the concrete durability was a major issue for Rion-Antirion Bridge due to aggressive environmental site conditions and the contractual requirement for a 120-year service life. The strategy chosen to protect the steel against the three major degradation risks of reinforced concrete (chemical attack by seawater, corrosion induced by chlorides, corrosion induced by CO2) relied mainly on a proper definition of exposure zones, the definition of appropriate concrete covers, and a proper characterization and evaluation of concrete itself.

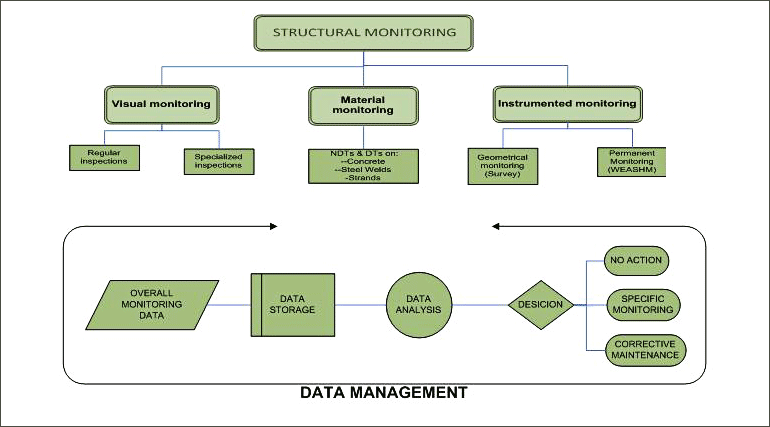

For the aforementioned reasons, in addition to periodic visual inspections, specific monitoring was also specified for the materials on a regular basis and for the crucial structural elements on a permanent basis (instrumented monitoring) in order to be able to analyze and evaluate the bridge status in any case.

Structural Management plan

A rational management plan has been developed in order to prevent and minimize the risk of structural deterioration. Complementary methods to visual monitoring methods (visual inspections) are implemented such as material and instrumented monitoring.

A rational management plan has been developed in order to prevent and minimize the risk of structural deterioration. Complementary methods to visual monitoring methods (visual inspections) are implemented such as material and instrumented monitoring.

The results of all type of monitoring are analyzed by the structural maintenance engineers, the Designer and other specialized suppliers/Consultants. Then every finding is assessed and any necessary actions to be taken are defined.

Application

The maximum safety level of the Rion-Antirion Bridge is achieved thanks to the use of latest developments in the field of bridge Management classifying it as one of the most innovative bridges even in this field - in addition to the other design & construction innovations.

Visual Monitoring

The program of visual inspections, is performed with the most advanced way exploiting the latest innovations of technology. The experienced structural inspectors of Gefyra S.A. structural maintenance department use tablet PC for each structural inspection. Specific software developed by Advitam has been properly customized to the specifications of the project as defined in the relevant Inspection and Maintenance Manual. During the inspection, the inspector fills in a check list for each structural element. In case a defect is identified, the type of defect is selected from an exhaustive list, the location of the defect is marked on the e-drawing, which is incorporated in the inspection software. Finally, a picture or a video can be associated with the relevant defect. Consequently, the quality of the data transmitted from the inspections to the analysis, which follows, is of high level. Additionally, factual reports can be created automatically in a manageable form (e.g. Word files).

The data from the inspection results are archived in a single database and follow the project throughout its service life. These are valuable data on the Bridge status and evolution.

The visual inspections are performed with permanent and/or temporary access platforms such as the deck gantry, the cradles for pier base internal etc. or with specialized equipment/personnel. It is worth-mentioning the rope access inspections of external surfaces of the pylons, of cables etc. with alpinists and the underwater inspections of external surfaces of the pier bases and the scour protection with ROV equipment and/or divers. Note that the use of state of the art equipment does not ensure the quality of the results unless the appropriate preparations and examinations are made (e.g. special methodologies, hardware and software) to define the desirable results. For example, the choice for using a ROV for the underwater inspections without making any provision for an effective mechanism to record its position (at any given moment) would lead to a huge amount of information (hours of videos) which in practice could not be processed and would be eventually useless.

Material monitoring

The term “material monitoring” means the tests (destructive or non-destructive) performed on the various materials from which the structural elements are made of. This complements the visual monitoring. Tests on welds of steel structural elements, fatigue tests on strands, durability tests on concrete etc. ensure that the performance of the materials themselves are monitored in detail in their environment. For instance, a special follow up program has been set, which defines specific tests to be performed on concrete during the service life on regular basis in order to measure the chlorides penetration, to determine the chlorides diffusivity and assess the overall service life of the structure.

Instrumented Monitoring

Except the monitoring via frequent visual inspections and material monitoring, the Rion-Antirion Bridge is also equipped with an innovative (permanent system) for its continuous and uninterrupted “surveillance” and “health” verification in real time, which is called Wind, Earthquake and Structural Health Monitoring (WEASHM).

Except the monitoring via frequent visual inspections and material monitoring, the Rion-Antirion Bridge is also equipped with an innovative (permanent system) for its continuous and uninterrupted “surveillance” and “health” verification in real time, which is called Wind, Earthquake and Structural Health Monitoring (WEASHM).

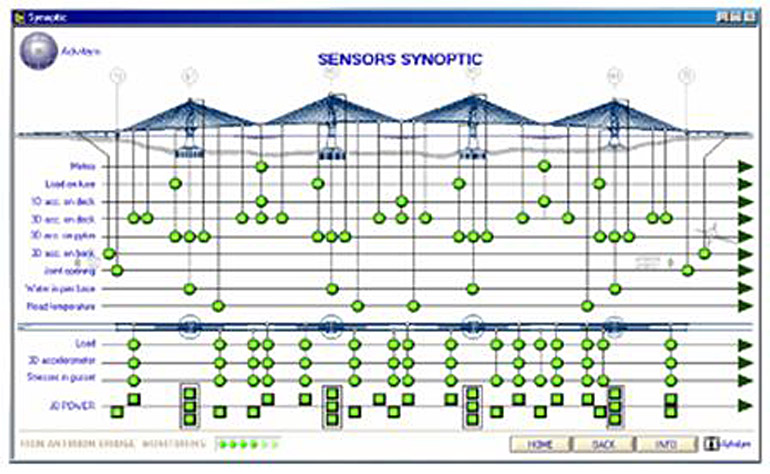

The WEASHM has been designed and installed by Advitam. The pylons, the deck, the cables and expansion joints are equipped with more than 100 sensors/300 channels. The loads and cable vibrations, the deck & pylon vibrations, the displacements on the expansion joints etc. are continuously recorded with high frequency sampling (100Hz) with the use of specialized hardware and software. Data are downloaded to specific hardware installed in the 4 pylons and a first processing is performed compared to the set thresholds. Simultaneously, the wind speed and direction, the ambient and deck temperature are measured since they are necessary parameters for the verification of the Bridge internal forces.

All data are transferred via optical fibers to a PC, which is installed for this purpose in the Operation building, and where they are further analyzed. Moreover, crucial information about the safe operation of the Bridge is transferred on the PC monitors of the Control Room either in form of measurements and/or messages.

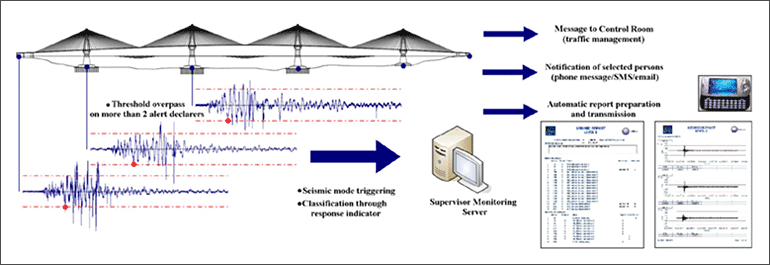

In special events such as earthquakes, high speed winds etc. special information messages on traffic management and on the proposed inspection level are sent to the Control Room in real time, while specific people can receive messages about the event as well as a report generated automatically 5 min. after the event has started; such report is sent by e-mail.

In special events such as earthquakes, high speed winds etc. special information messages on traffic management and on the proposed inspection level are sent to the Control Room in real time, while specific people can receive messages about the event as well as a report generated automatically 5 min. after the event has started; such report is sent by e-mail.

Finally, geometrical monitoring with classical geodetic survey methods is performed at regular intervals (non-permanent system) in order to check the geometry of the Bridge and the permanent tectonic movements on the two shores and at pier locations.